On December 29, 1970, President Nixon signed the Occupational Safety and Health Act, which was enacted on April 28, 1971. For 50 years, OSHA has played an integral role in the safety of heating, air conditioning, ventilation, and refrigeration professionals.

So What Does OSHA Do?

OSHA is part of the United States Department of Labor. Their goal is to ensure safe and healthy work conditions through setting and enforcing workplace standards.

The OSHA offers training, outreach, education, and assistance to help employers and employees create secure working conditions. The OSHA’s administrator answers to the Secretary of Labor, who is appointed by the President of the United States.

OSHA covers these HVAC job factors:

- Hazardous materials: Hazardous materials include gases and chemicals, such as refrigerants.

- Confined space entry: HVAC technicians often operate in confined spaces, like when they are installing ductwork.

- Electrical Standards: HVAC professionals directly work with electricity, like when they are connecting HVAC systems to power sources.

- Respiratory protection: In some extreme cases, HVAC workers may need respiratory protection if toxic airborne substances are present while they’re performing maintenance or repair work.

- Machinery: HVAC technicians who work on construction sites likely do so among heavy machinery, such as cranes or pavers.

How does the Occupational Safety and Health Act protect HVAC workers?

OSHA not only provides guidelines for worker safety, but also helps outline the risks that HVACR technician can be exposed to on the job.

Refrigerant Safety

A primary safety concern when working with refrigerants is oxygen deprivation. OSHA regulations provide detailed instructions on how to use these refrigerants safely, how to store them and how to react if there is refrigerant exposure on the job.

Preventing Falls

Falls are among the most common causes of on-the-job fatalities, especially in the construction industry. It is so common that it is included as part of OSHA’s “Fatal Four.” OSHA regulations require fall arrest equipment for anyone working above a certain height, which ranges from four to eight feet depending on the industry, or on a particular grade of roof.

Managing Confined Spaces

Working in confined spaces is part of the job for HVAC technicians, especially when they have to install wiring and ductwork in attics, basements, and crawl spaces. In addition to the challenge of working in small spaces, there is an increased risk of carbon monoxide (CO) and carbon dioxide (CO2) exposure if the space does not have adequate ventilation.

Electrical Safety

Installing new HVAC units or repairing existing ones means working with electrical systems. Electricity-related accidents might not be common enough to make it into the Fatal Four, but they are still a hazard that OSHA addresses for HVAC employees.

How does FIELDBOSS HVAC software help techs stay safe on the job:

- Technicians can easily view what work has previously been completed on-site.

- Work orders or digital forms with standardized instructions guarantee that field technicians are adhering to the proper safety processes in the field. For instance: they are unable to move to the subsequent stage of the work order without verifying that the main power has been shut down.

- Access to comprehensive data about equipment.

- Techs can emphasize safety concerns via pictures and videos.

- Updated job site information is easily shared; you can dispatch the latest health and safety forms, or notify field workers about new regulations.

- Links to tips, how-to-videos, and regulation manuals are easily accessible on their mobile device.

- Management can use past health and safety data to help predict and avoid potential incidents.

- You can view the quantity of incidents per region, office, and/or team, and identify the best and worst performing sites and teams.

- Share top performers to determine best practices throughout the company.

- Safety data and reports can be easily accessible to both internal stakeholders and industry regulators.

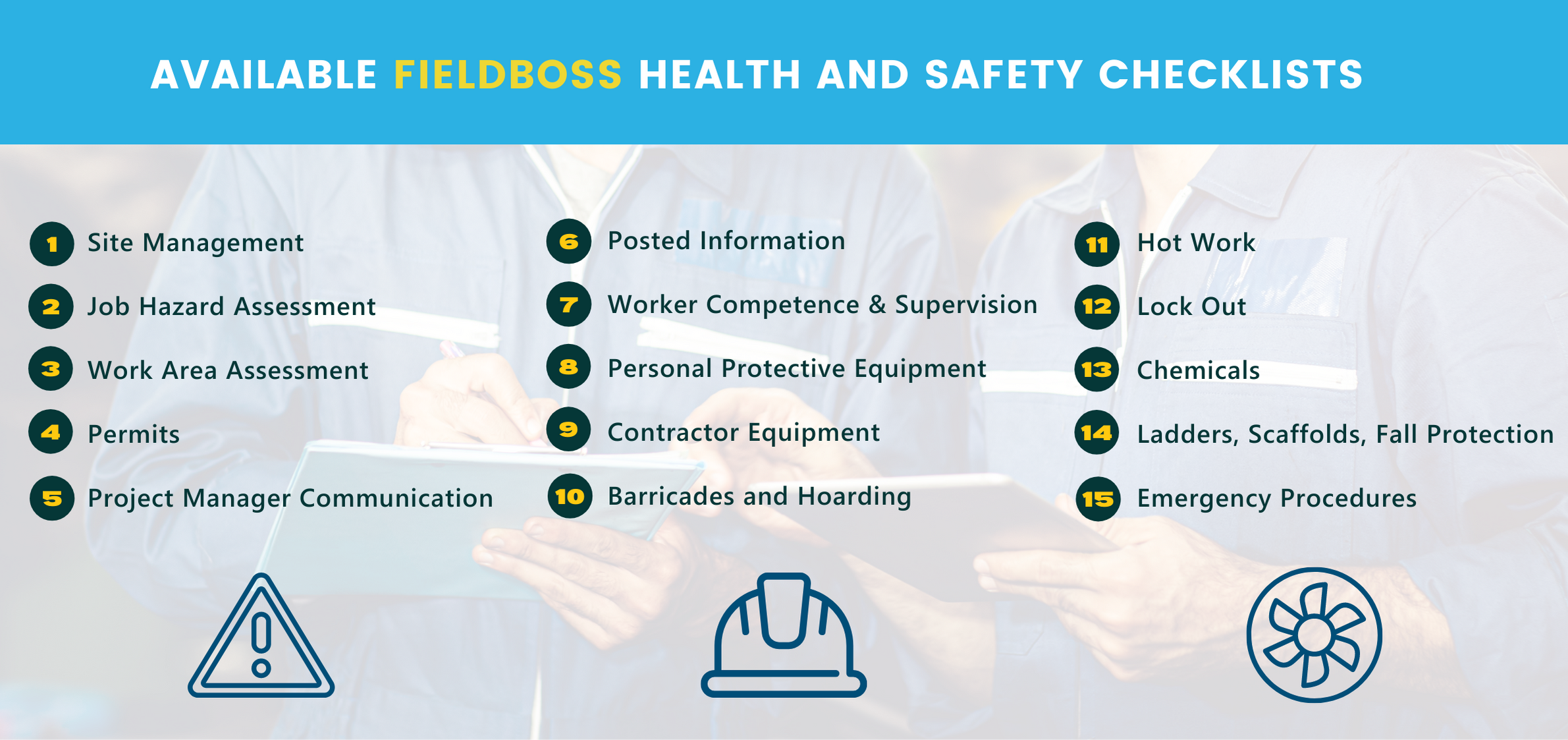

Checklists

FIELDBOSS mobile has many health and safety checklists that help your HVACR business ensure that all procedures are clear, consistent, effective and can be created in a way that is easy for your field staff to access and complete.

FIELDBOSS customers have a significant added benefit in that the solution is embedded as part of the business management system, so there is no need for additional software to license, manage and support.

FIELDBOSS Mobile Checklist Screenshots

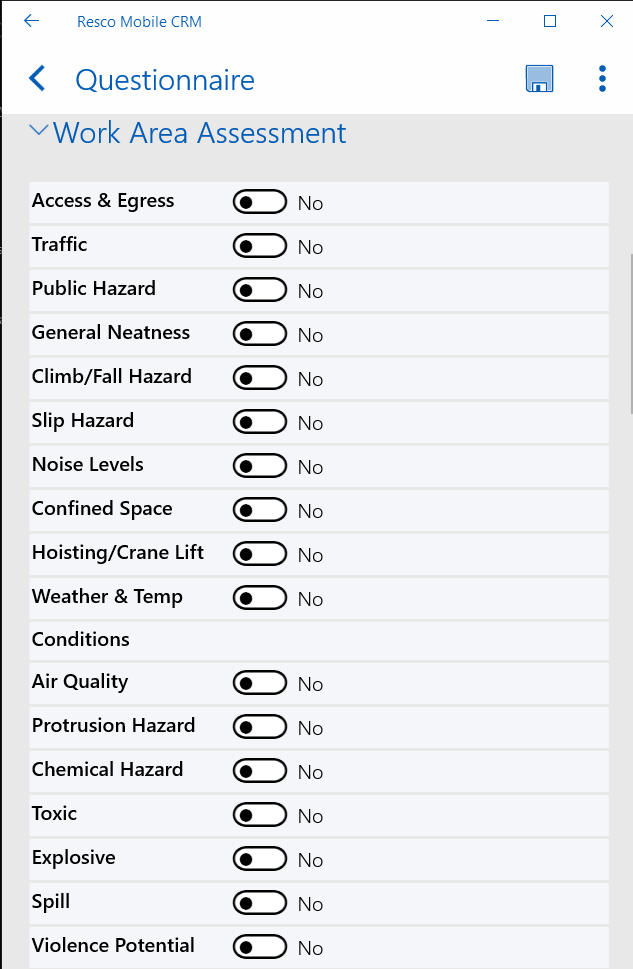

Work Area Assessment

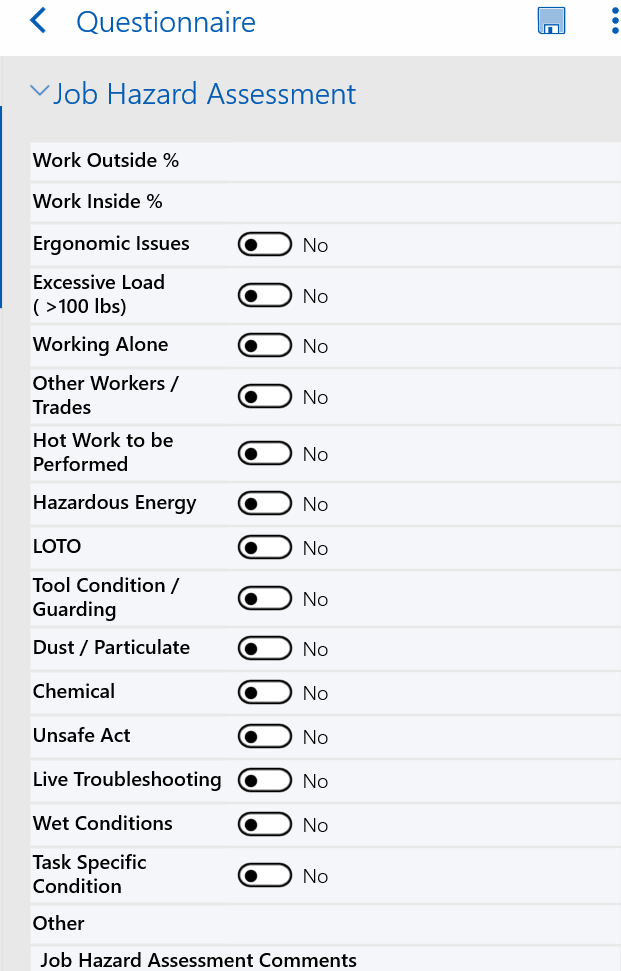

Job Hazard Assessment

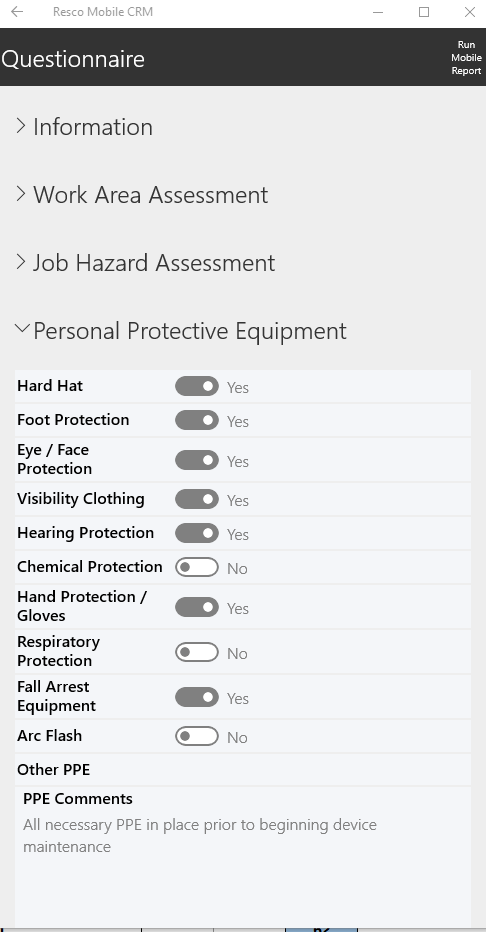

Personal Protective Equipment

With the proper safety protocols in place, your team can:

- Minimize accident risks and help prevent workplace injuries.

- Enhance compliance with laws and regulations.

- Reduce costs, including considerable drops in workers’ compensation premiums.

- Create a safe workplace culture.

- Increase efficiency and improve overall business operations.

OSHA has been around for five decades. As new techniques and technologies emerge, OSHA regulations will continue to evolve. But if you don’t have a way to properly enforce the regulations then you are putting your team and your company at risk. With the right software, you can ensure the greatest level of safety for your field team by providing the necessary tools to stay compliant, avoid headaches, and keep your team safe and informed. Contact us or schedule a free demo for more information.