The Occupational Safety and Health Administration (OSHA) announced its Top 10 most frequently cited workplace safety standards for fiscal year 2021.

Patrick Kapust, deputy director of OSHA’s Directorate of Enforcement Programs, presented the list virtually during the 2021 National Safety Committee’s (NSC) Safety Congress & Expo.

Overall, the number of inspections and violations issued by OSHA in FY 2021 decreased compared to the previous year. The overall number of violations recorded in the top 10 list in fiscal year 2021 only amounts to 21,092—the lowest number in at least five years. The decline in violations is likely because less inspections took place in fiscal year 2021, leading to less violations reported. Kapust says that’s due to the pandemic, but he advises that “We are still on the job, we still do inspections.” He did add that inspection resources have shifted to workplaces where COVID-19 hazards are more likely to exist.

“Throughout the pandemic workplace safety has become more important than ever,” said Lorraine Martin, NSC president and CEO. “Although incredible advancements are made in safety each year, the OSHA Top 10 list reminds us that we must continue to pinpoint areas where we can improve so we can better prioritize workplace safety in the future world of work.”

OSHA’s publicly released list isn’t specific to the construction industry. However, using the agency’s Frequently Cited OSHA Standards search tool, you can filter results by North American Industry Classification System (NAICS) to get a specific list of the top OSHA violations in your industry in 2021.

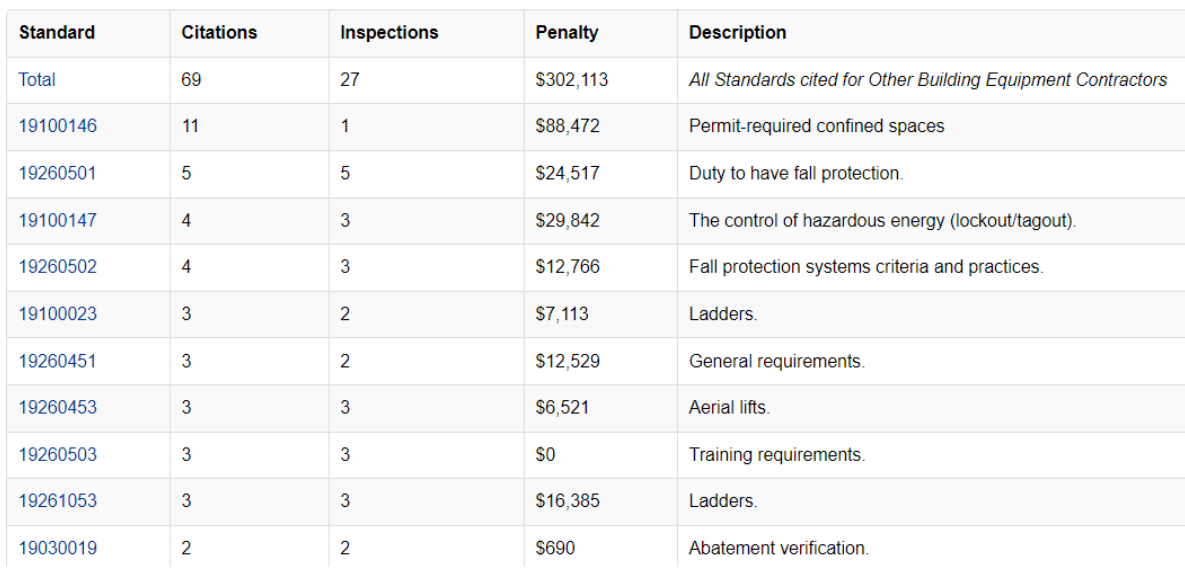

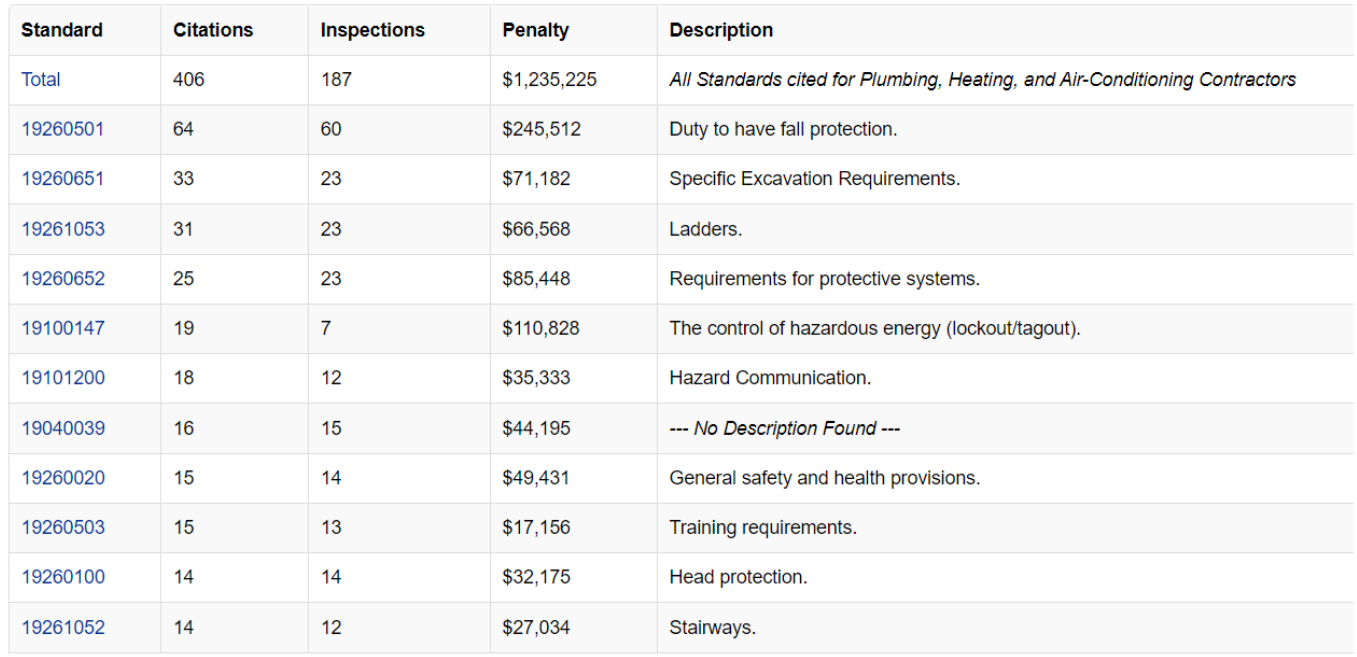

Here are the top 10 most cited OSHA violations for elevator and HVAC contractors in 2021:

NAICS Code: 238290 Other Building Equipment Contractors

NAICS Code: 238220 Plumbing, Heating, and Air-Conditioning Contractors

There are several steps your field service company can take to avoid OSHA fines and prevent worker injuries, illnesses, and deaths.

10 ways FIELDBOSS can improve technician safety:

- Technicians can easily view what work was previously completed on-site.

- Work orders or digital forms with mandatory or sequenced actions guarantee that field technicians are following appropriate safety processes in the field. For example: technicians cannot move to the next stage of the work order without verifying that the main power has been shut down.

- 24/7 access to comprehensive data about equipment.

- Techs can highlight safety concerns via pictures and videos.

- Updated job site information is easily shared, the latest health and safety forms are always updated, and field workers can be quickly and easily notified about new regulations.

- Links to tips, how-to-videos, and regulation manuals are easily accessible on their mobile device.

- Management can use past health and safety data to help predict and avoid potential incidents.

- You can view the quantity of incidents per region, office, and/or team, and identify the best and worst performing sites and teams.

- Share top performers to determine best practices throughout the company.

- Safety data and reports can be easily accessible to both internal stakeholders and industry regulators.

*Learn about FIELDBOSS Health & Safety Checklists here.

FIELDBOSS contractor management software can help you provide the greatest level of safety for your technicians by giving you the tools you need to stay safe and compliant. Contact us for a free demo or for more information.