A flexible, connected scheduling software is critical for field service organizations that are looking for ways to provide superior customer service while reducing operating costs. Customers increasingly want faster service resolution at a lower cost; improving scheduling and field technician efficiency is one of the ways to effectively achieve that goal.

A flexible, connected scheduling software is critical for field service organizations that are looking for ways to provide superior customer service while reducing operating costs. Customers increasingly want faster service resolution at a lower cost; improving scheduling and field technician efficiency is one of the ways to effectively achieve that goal.

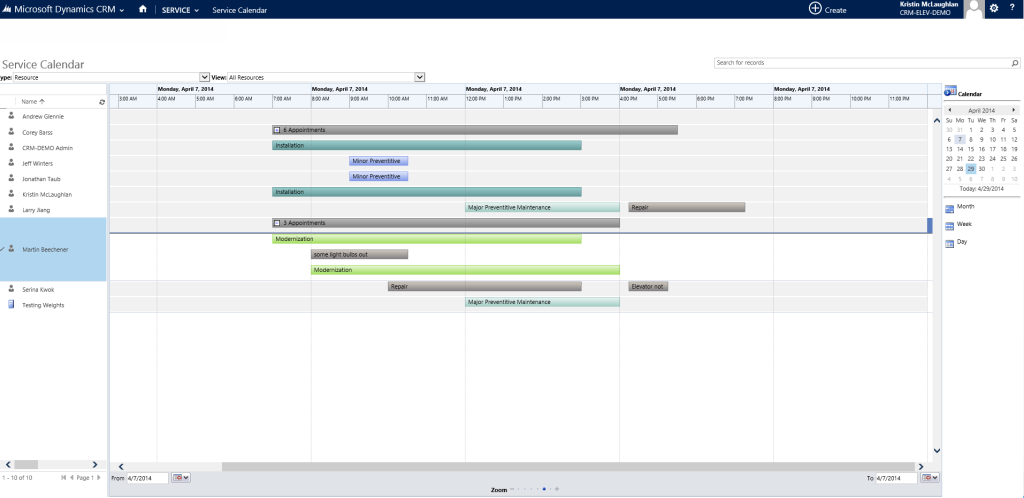

When searching for a field service management software solution for your business, it is important to look for one that integrates the mobile field service with the back office, allowing data from the technicians, the scheduling engine, and the business systems to be seamlessly integrated. This not only improves scheduling efficiency, it also provides enhanced visibility into the service operation so that managers can better measure performance and create an auditable data trail to establish a service baseline, improve processes, and reduce costs. A comprehensive solution will give field service organizations the opportunity to improve management of costs associated with the schedule/dispatch operation and return service visits that can be avoided via improved scheduling.

Automated dispatching, scheduling, and routing can have a direct impact on service costs by:

Improving Technician Productivity

Rather than managing their schedules and dealing with dispatchers, technicians can spend more time working with customers and completing service activities. Having access to a map allows technicians to not only efficiently complete their routes but also quickly and easily locate the nearest parts depot. Improved scheduling makes technicians more efficient and productive, enabling them to complete more service calls per day. Even adding one work order per technician per day can increase revenues without adding staff. And by helping them work more efficiently, service companies can reduce or eliminate costly overtime.

Improving Scheduling of Preventive Maintenance

Scheduling preventive maintenance (PM) work between break/fix calls can be a challenge. By automating and incorporating PM calls into the scheduling system, they can automatically be assigned based on technician location and other factors. If technicians have some free time between jobs, they can easily see what maintenance activities are coming up, what the closest location is and take advantage of what otherwise would have been wasted time. Technician proficiency helps improve customer loyalty and can generate add-on business.

Reducing Non-Value-Added Time

In a manual dispatch environment, technicians and dispatchers spend an enormous amount of time on the phone, leaving and responding to messages. An automated solution can eliminate phone calls and reduce reliance on direct contact between the dispatcher and the field saving hours per day allowing schedulers and technicians to be focusing their time on satisfying customers.

Improving First Time Fix Rate

One of the most aggravating incidents for any customer is when a return trip needs to be made because the technician couldn’t resolve the issue on the first visit. First-time fix rate is one of the most vital metrics in measuring field service performance. For companies burdened by low first-time fix rates, the extra expenses required to resolve jobs not fixed the first time add up quickly: multiple extra truck rolls, extra labor, increased dispatch energy and attention, and lost service opportunities elsewhere. The higher your first-time fix rate is, the greater capacity your team will have to make more service calls in a day and service new customers at the lowest possible operational cost. An intelligent dispatch/scheduling solution plays a key role in making that possible.

Reducing Drive Time

Automated scheduling only solves part of the problem relative to getting the right techs to a given location. Routing those technicians is equally important. Routing systems can guide technicians efficiently from one job to the next. Better routing can reduce the amount of drive time between jobs helping technicians arrive on time, complete more work orders per day and even reduce fuel consumption. With the cost of fuel continuing to rise, reducing unnecessary drive time can be a major contributor to reducing operational costs.

Reducing Dispatcher-to-Technician Ratios

Manual dispatching requires a high number of dispatch personnel to manage a given group of technicians, primarily because of the amount of time spent on the phone and dealing with a daily barrage of scheduled and emergency service visits for multiple customers. By automating these processes, the total number of dispatchers can be significantly reduced.

Optimal field service automation is more than just electronically managing work orders. A fully integrated field service solution is required in order to increase productivity while lowering costs. A key component of this solution is a highly automated scheduling, dispatch, and routing system that will ensure that qualified technicians arrive at the job site on time, with the right tools and parts while taking into account technician availability, location, travel time, SLA requirements, and many other factors. The result is improved technician productivity and customer service, and a reduction in operational costs.

Contact FIELDBOSS and see how we can help you get your technicians where they need to be while reducing your operational costs to increase revenue.